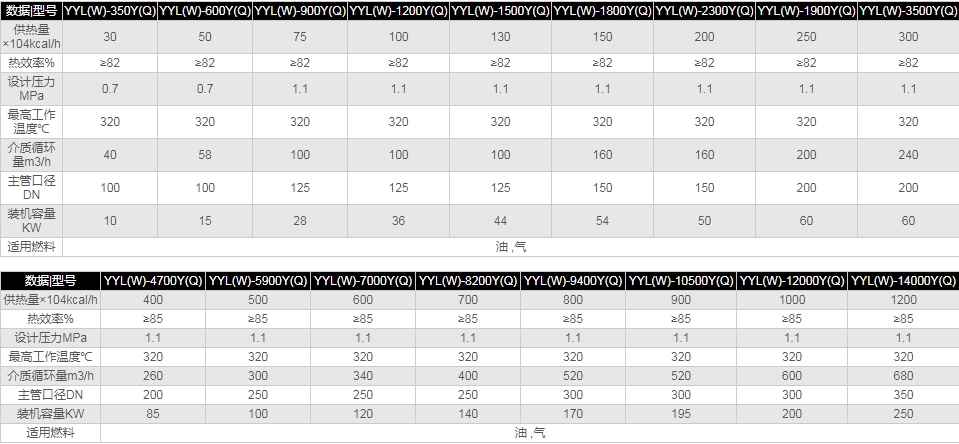

產品範(fàn)圍

供熱量:(300-1500)×104Kcal/h,設計壓力:1.1MPa

YYL(YYW)係列有機熱載(zǎi)體爐(lú)為快裝式強製循環燃油(氣)鍋爐。本係列(liè)鍋爐本體(tǐ)受熱麵結構緊湊,受熱麵(miàn)由內、中(zhōng)、外(或內、外)密排的圓盤管構成;內盤管(guǎn)為輻射受熱麵(miàn),中、外盤管與內盤管的外表(biǎo)麵構成對流受熱麵。燃料在內盤管組成(chéng)的燃燒室內燃燒放熱,經輻射受熱麵吸收大部分熱量後,高溫煙氣進入對流受熱麵進行(háng)換熱,出鍋爐後在空氣預(yù)熱器中加熱(rè)鍋爐燃燒所需(xū)的空氣,再經除塵器(qì)由(yóu)引風機將煙氣送至煙囪排入大氣

安裝方便靈活,隻要將鍋爐就位於其基礎上即可。

受熱麵采用密排圓盤管,受熱麵(miàn)布置充足,降低管子表麵熱負荷,是導熱油使用更an全。

爐膛尺寸與燃燒火焰相匹(pǐ)配,采用了(le)正壓燃燒,輻射換熱(rè)效(xiào)率高(gāo)。

鍋爐結構緊湊,大大節約了(le)鍋爐房的占地麵(miàn)積(jī)。

大型鍋爐尾(wěi)部設(shè)置空氣預熱器,提高鍋爐效率。

Product Range

Heat supply: (300-1500)×104Kcal/h, design pressure: 1.1MPa

YYL (YYW) series of organic heat carrier furnace for fast-loading forced circulation fuel (gas) boiler. This series of boiler body heating surface compact structure, the heating surface by the inner, outer (or inner and outer) close-packed disk tube composition; inner coil radiation heating surface, the outer coil and the outer coil The surface constitutes convection heating surface. The fuel is combusted and radiated in the combustion chamber formed by the inner coil. After the radiant heating surface absorbs most of the heat, the high-temperature flue gas enters the convection and heating surface for heat exchange. After the boiler heats the air required for the boiler combustion in the air preheater , And then by the dust catcher by the induced draft fan to the chimney into the atmosphere

Installation is extremely convenient and flexible, as long as the boiler is located on the basis of it.

Heat surface with close-packed disk, heating surface layout sufficient to reduce the thermal load on the pipe surface, the use of thermal oil is more secure.

Furnace size matches the combustion flame, positive pressure combustion is used, and radiation heat exchange efficiency is high.

Boiler structure is compact, greatly saving the boiler room area.

Air boilers are installed at the rear of large boilers to improve boiler efficiency.

注:由(yóu)於本公司產品(pǐn)不斷改進,以上產品參數將不斷更新(xīn),本(běn)頁所列僅供參考。表列鍋爐品(pǐn)種為(wéi)本廠代表產品,如需其他型號參數鍋爐可參閱有(yǒu)關圖紙資料